Cruise Ship Propeller Cost

It costs more than a cool billion dollars for the biggest cruise ship to be built and that is just talking about having one built.

Cruise ship propeller cost. Propeller moves forward 10inches for every complete turn it has a 10inch nominal pitch. Unlike airplanes which require tremendous propeller speeds to provide the forward motion needed for flight cruise ship propellers do not need to turn as fast. The price depends on the size material and amount of work required.

Propellers and Rudders Ducted propeller 10 all ship types except ferry and cruises medium 4-15 years Medium Propellers and Rudders Contra-rotating propellers 13 only special ship types long 15 years High Propellers and Rudders Wheels 10 all ship types except ferry and cruises short. The cruise industry is a fast-growing category in the leisure travel market and cruise performance monitoring for your. We all know the story of the Titanic of how the biggest ship of its time sank after it struck an iceberg.

Manouvrability - with Azipods or similar and a small bow thruster is it possible to go alongside without tugs assisting. In reality since the propeller is attached to a shaft it will not actually move forward but instead propel the ship forward. PROPELLER RECONDITIONING and RE-PITCHING SERVICE.

Cruise industry began in 1844 when ships were propelled by steam engines performing the driving of propellers by using steam as working fluid. He was fired for not adhering to the code of conduct in his contract. At the shipowners request Thordon Bearings the market leader in water lubricated bearing.

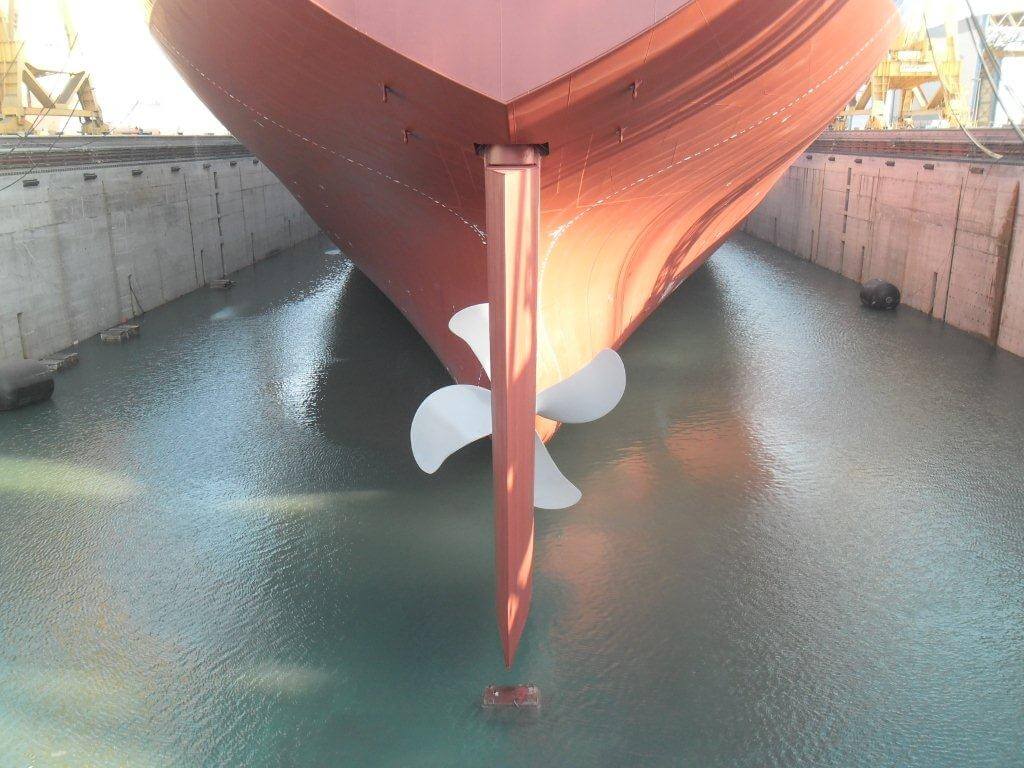

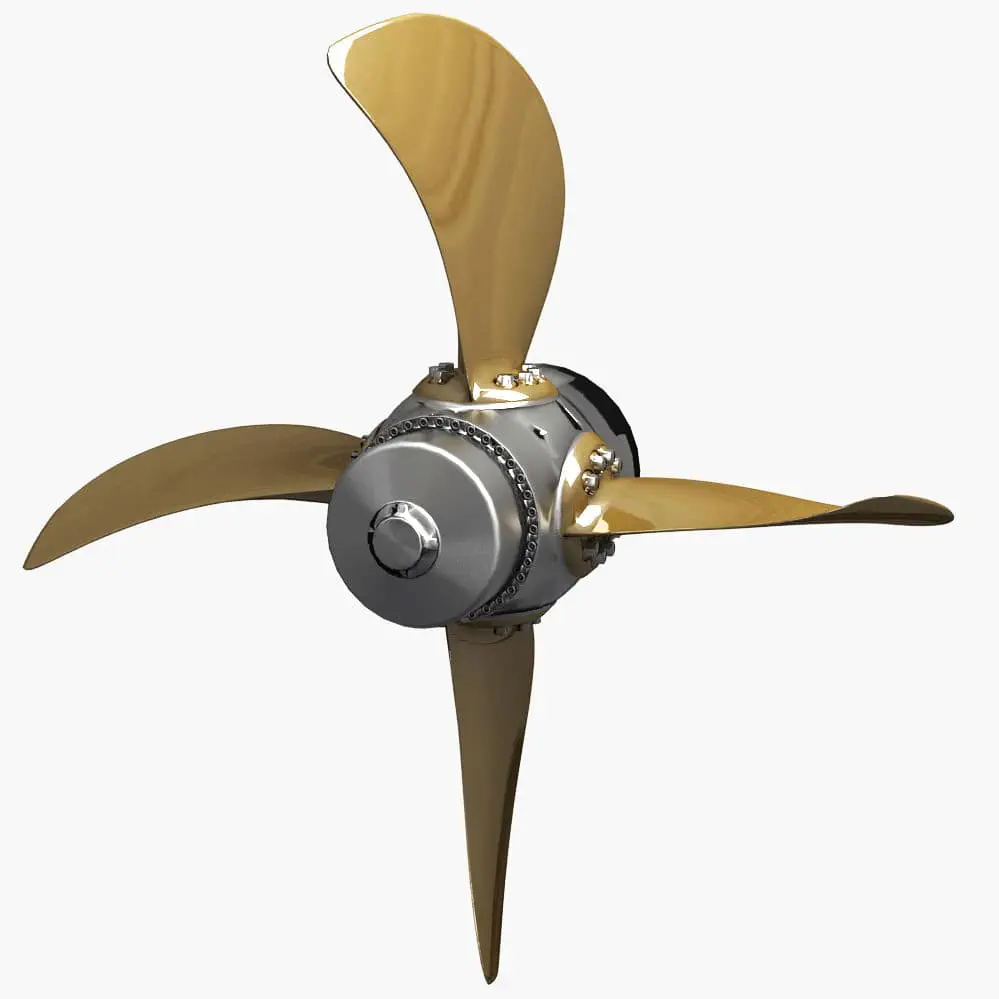

Azipod quickly established a new propulsion standard for icegoing vessels and has become the market leader in the cruise ship segment. Economy - Azipod equipped vessels use less fuel. All cruise ships rely on propellers to push them through water.

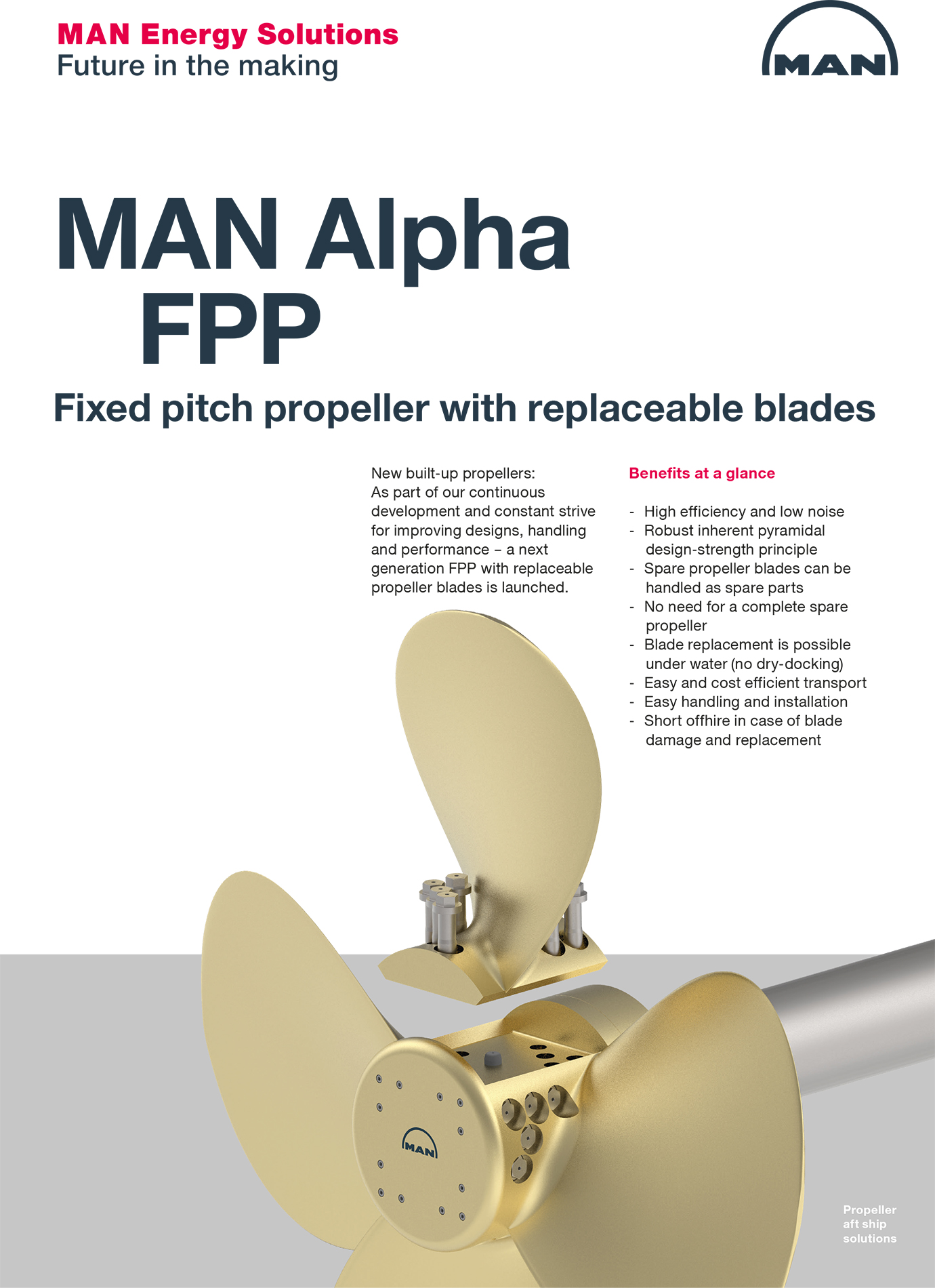

As you might imagine driving something the size of a skyscraper through narrow waterways and then precisely docking it between various obstacles is no easy task. This represents annual fuel cost savings of more than USD 120000 at fuel prices in July 2010. In this case the propeller is cast in one piece and is made of a complex.